Advanced Composite Materials for Engineering

Advanced composite materials - ACMs are also identified as advanced polymer matrix composites. These materials are generally characterized or determined by unusually high power fibers with high stiffness, or modulus of elasticity, when compared to other materials. While they bound together by weaker matrices also. These are the advanced composite materials (ACM) in comparison to the composite materials commonly are in use such as reinforced concrete, or even concrete itself. The high strength fibers will also be in low density while occupying a large fraction of the volume.

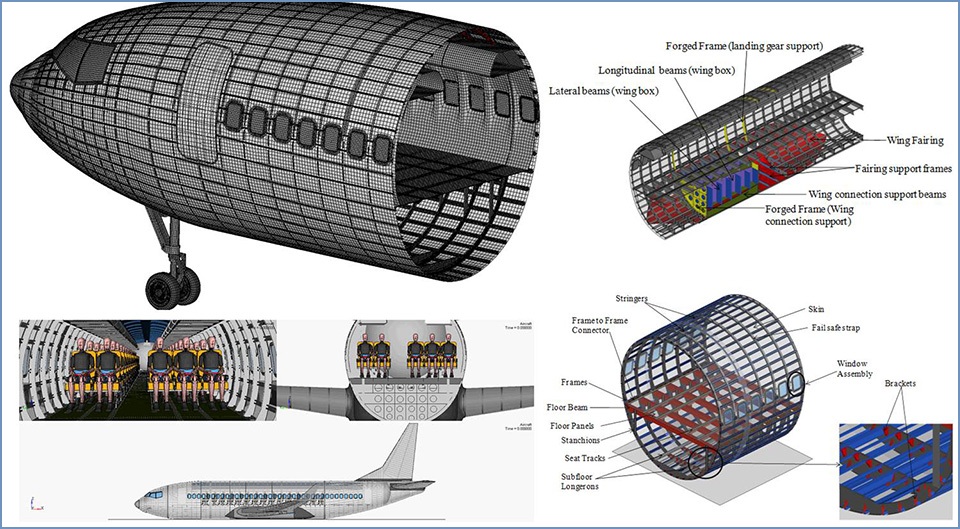

These advanced composites exhibit desirable physical and chemical properties which include light weight coupled with high elasticity and strength along the direction of the reinforcing fiber, temperature and chemical resistance, dimensional stability, contract performance, and relatively easy processing. The advanced composites are replacing metal components in many uses, particularly in the aerospace industry.

Composites are classified as per their matrix phase. These classifications are polymer matrix composites - PMCs, ceramic matrix composites - CMCs, and metal matrix composites - MMCs. Also these materials within different categories are often called " advanced", Often they are combined with the properties of high axial, longitudinal force values and high axial, longitudinal hard values, with low weight, corrosion resistance, and in some cases with the special electrical properties too.

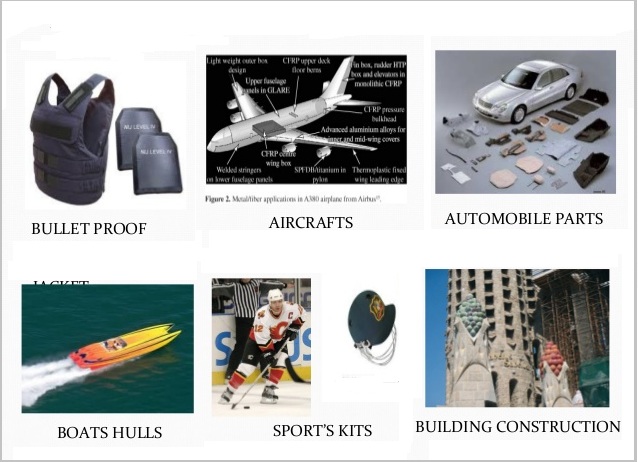

However the advanced composite materials are broad and proven applications in the aircraft, aerospace, and sports equipment sectors. Even more specially ACMs are very attractive for aircraft and aerospace structural parts. These advanced materials are also involved in developing for the NASA's Advanced Space Transportation Program, armor protection for Army aviation and for high-temperature shafting for the Comanche helicopter, and for the Federal Aviation Administration of the USA.

In addition the ACMs have a decade's long history in helping the military and government aerospace industries. However, much of the technology is latest and not accessible formally in secondary or undergraduate education. While the technology of advanced composites manufacture is continually developing.

Overview

Manufacturing Advanced Composite Materials is a multibillion-dollar industry worldwide; but the composite products range from skateboards to components of the space shuttles. While the industry is generally divided into two basic segments — industrial composites and advanced composites. Many composites that manufacturing processes are common to both segments.

Industrial Composites

The industrial composites industry is famous and been in place for over 40 years in the U.S. This is a large industry that utilizes various resin systems including epoxy, polyester, and other specialty resins. These materials, along with a catalyst or curing agent mixed with some type of fiber reinforcements or naturally glass fibers are used in the production of a wide spectrum of industrial components and consumer goods like —boats, piping, auto bodies, along with other parts and components.

Advanced Composites

The Advanced composite materials industry is characterized by the use of expensive, high-performance resin systems and high-power, high-rigidity fiber support. These materials have also been adopted for use by the sporting goods suppliers who make or sell high-performance equipment to the golf, tennis, fishing, and archery markets; as well as in the swimming pool industry with Composite wall structures.

The suppliers of advanced composite materials tend to be larger organizations that are capable of doing the research and development which is necessary to provide these high-performance resin systems needed in this segment of the industry. However the end-users also tend to be large, and many are in the aerospace and aircraft businesses.

Thermosets & Thermoplastics

Advanced composite systems are further divided into two basic types, Thermosets and thermoplastics. Thermosets are by far the major type in use today. Thermosets are subdivided into several resin systems including epoxies, polyurethanes, phenolics and polyimides. Among them; epoxy systems are currently dominated by the advanced composite industry.

Whereas Thermoplastics represent a comparatively small part of the ACM industry. They are typically supplied as non-reactive solids; which means no chemical reaction occurs during the processing. These materials require only heat and pressure to form the finished part. Unlike the Thermosets, the thermoplastics can regularly be reheated and transformed into another shape, if desired.