Aluminum Electrolytic Capacitor - I

An aluminum electrolytic capacitor is usually called an electrolytic capacitor (e-cap), which is a capacitor whose anode (+) consists of pure aluminum foil with an imprinted surface, it is covered with a uniformly very thin fence layer of insulating aluminum oxide, which operates as a dielectric.

While the electrolyte, which covers the rough surface of the oxide layer, operates as the second electrode, the cathode (-). However the E-caps have the largest capacitance values per unit volume when compared to the two other main conventional capacitor family, ceramic and plastic film capacitors, but much smaller capacity than similar sized super capacitors.

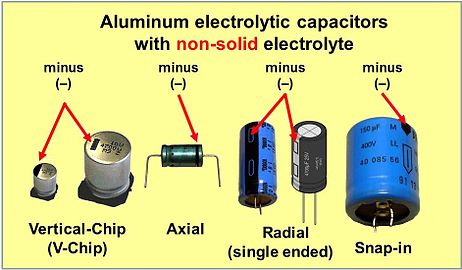

However, the aluminum electrolytic capacitors are divided into three subfamilies by the type of electrolyte:

non-solid —liquid, wet aluminum electrolytic capacitors,

- Solid manganese dioxide aluminum electrolytic capacitors, and

- Solid polymer aluminum electrolytic capacitors

The aluminum electrolytic capacitors with non-solid electrolyte are of an inexpensive type and also available with wide range of sizes, capacitance and voltage values. They are made with capacitance values starts from 0.1 µF up to 2,700,000 µF (2.7 F), thus these capacitors are rated voltages which value from 4 V up to 630 V. The liquid electrolyte provides oxygen for re-forming or self-healing of the dielectric oxide layer. However, it can evaporate through a temperature dependent drying-out process, which causes electrical parameters to float, preventive the service lifetime of the capacitors.

Due to their relatively high capacitance values, aluminum electrolytic capacitors have low impedance values if there are lower frequencies like mains frequency. These are typically used in power supplies, switched-mode power supplies and DC-DC converters for smooth and buffering rectified DC voltages in many electronic devices as well as in industrial power supplies and occurrence converters as DC link capacitors for drives, inverters for photovoltaic, and converters in wind power plants. Special types are used for energy storage, for example in photoflash or strobe applications or for frequency coupling in audio applications.

Aluminum electrolytic capacitors are polarized capacitors because of their anodization principle. They can only be operated with DC voltage applied with the correct polarity. Operating the capacitor with a wrong division or with AC voltage leads to a short circuit and can wipe out the component. The exceptions are the bipolar aluminum electrolytic capacitor, which has a back-to-back configuration of two nodes in one case and can be used in AC applications.

Oxide Layer

The basic principle of anodic oxidation, in which, the voltage is applied to a current source, an oxide layer is formed on a metallic anode. While the electrolytic capacitors use a chemical feature of some special metals, earlier called "valve metals". Applying a positive voltage to the anode material in an electrolytic bath forms an insulating oxide layer with a thickness corresponding to the applied voltage. This oxide layer acts as the dielectric in an electrolytic capacitor.

After forming a dielectric oxide on the rough anode structures, a counter-electrode has to match the rough insulating oxide surface; this is provided by the electrolyte, which acts as the cathode electrode of an electrolytic capacitor. Electrolytes may be non-solid - wet, liquid or solid. Non-solid electrolytes, as a liquid medium that has an ion conductivity caused by moving ions, are relatively insensitive to voltage spikes or current surges. Solid electrolytes have an electron conductivity, which makes solid electrolytic capacitors sensitive to voltages spikes or current surges. The anodic generated insulating oxide layer is destroyed if the polarity of the applied voltage changes.

Every electrolytic capacitor in principle forms a plate capacitor whose capacitance is greater the larger the electrode area A and the permittivity ε, and the thinner the thickness (d) of the dielectric.

We will see more on the topic in next coming blog.