Flexible Ship Electric Power System Design

The first electrical power system was installed on the USS Trenton in the year 1883 (Ykema 1988). While this system consisted of a single dynamo supplying current to 247 amps at a voltage level of 10 volts d.c. Until 1914 to 1917 period, the early electrical power systems were mainly d.c., that means the loads consisting were mainly of motors and lighting. It was during World War I that 230 volt and 60-hertz power systems were introduced into naval vessels. Since World War II the ship’s electrical systems have sustained to improve, including the use of 4,160 volt power systems and at this period the electronic solid-state protective devices were introduced and these protective devices were developed to monitor the essential parameters of the electrical power systems and then through built-in logic; determine the degree of configuration of the system necessary to limit the break to continuity of electric service for the vessel — Ykema 1988.

Fuses are the oldest form of protective devices which are used in electrical power systems in commercial systems and on navy vessels, in this flow circuit breakers were added around the turn of the century. However, the first electronic solid-state overcurrent protective device used by the Navy was installed on the 4,160 power system in Nimitz class carriers. While the Navy systems of today supply electrical energy to complicated weapons systems, communications systems, operational systems, and navigational systems. To maintain the availability of energy to the connected loads to keep all the systems and equipment operational, the navy electrical systems utilize fuses, circuit breakers, and protective relays to interrupt the smallest portion of the system under any irregular condition.

However, the existing protection system has several shortcuts in providing continuous supply under battle and certain major failure conditions. The control strategies which are implemented when these types of damage take place are not effective in separating only the loads affected by the damage and are highly reliant on human intervention to manually reconfigure the distribution system to restore supply to healthy loads.

The new techniques which aim to conquer the shortcomings of the protective system, and these techniques are composed of advanced monitoring and control, automated failure location, self-optimizing under partial failure, and automated intelligent system reconfiguration and restoration.

While these new techniques will help eliminate human mistakes, make intelligent reconfiguration decisions more rapidly, and reduce the manpower required to perform the functions. They will also provide optimal electric power service through the current system. With fewer employees being available on ships in the future, the presence of this automated system on a ship may mean the difference between disaster and endurance.

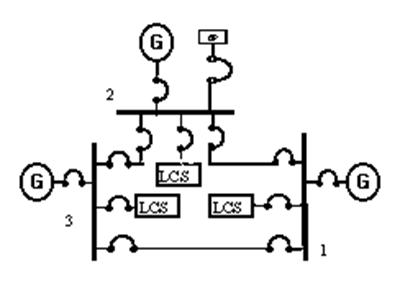

The two new architectures for designing ship power systems have been introduced as— the current source current intensive (CSCI) and the articulate system. The fundamental characteristics of these systems appear that the CSCI is the more ambitious of the two architectures. By this virtue will also be realizable in a more distant future. However, some aspects of the articulate system architecture, as discussed in this blog can be implemented in the short term also. A flexible AC distribution systems, within the perspective of flexible AC transmission systems -FACTS; Hingorani 1993; which are now undergoing rapid development and implementation, can be regarded as a subset of the family of control methodologies which comprise the realm of articulate systems. Undoubtedly as the CSCI and articulate system designs progress, problems will arise; however, the developments in superconductors, superconducting magnetic energy storage, and power electronics will provide a wide technical base to solve these troubles. These advanced system architectures suggest better ways for implementing the power distribution system in next generation ships. They also provide ways to bring new technologies, better system operation, to existing ships during its retrofitting for service life extension.