Fractal Robot

Fractal Robots is an rising new service that promises to transform every aspect of human technology. Did you know that Fractal robots are the objects made from cubic bricks which can be controlled by a computer to change shape and reconfigure themselves into objects of different shapes. However these cubic powered bricks can be programmed to move and shuffle themselves to change shape to make objects like a house potentially in a few seconds.

While this technology has the potential to penetrate every field of human work like construction, research, medicine and others. Fractal robots can allow buildings to be built within a day, and also help you to perform sensitive medical operations to assist in laboratory experiments. This technology is called Digital Matter Control and is implemented here with a machine called robotic cubes and this entire technology is called Fractal Robot Technology. In addition Fractal Robots have built-in self repair which means they can carry on without human intervention.

Introduction

The birth of every new technology is the result of a mission for automation of some form of human work. This has led to many inventions that have made life easier for us. Fractal Robot is a science that promises to revolutionize technology in a way that has never been witnessed before.

What are Fractals?

A fractal is anything which has a substantial measure of exact or statistical self-resemblance. Wherever you look at any part of its body it will be alike to the whole object.

Fractal Robots

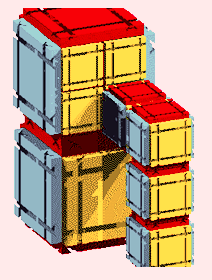

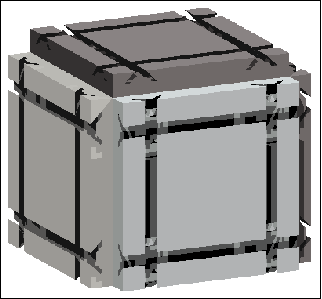

A Fractal Robot physically resembles itself according to the meaning above. The robot can be animated around its joints in a uniform way. However, such robots can be straight forward geometric patterns or images that look more like natural structures such as plants. This patented product however has a cubic like formation. The figure below shows a collection of such cubes.

Fractal Robots start at one size to which partially size or double size cubes can be attached respectively. This is what makes them fractal. So a fractal cube can be of any size; while the smallest expected size is between 1000 and 10,000 atoms wide. These cubes are embedded with computer chips which control their movement. Thus, these chips can be programmed to configure themselves into any shape. The implication of this concept is very powerful, and can be used to build buildings, bridges, instruments, tools and almost everything else you can think of. It can be done with hardly any manual interference. These robots can assist in production and manufacture of goods thus bringing down the manufacturing price down dramatically.

Simple Construction Details

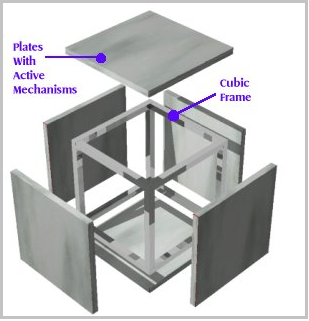

Considerable effort has been taken in making the robotic cubes as simple as possible after the creation has been conceived. The design is such that it has fewest possible moving parts so that they can be mass produced. However, the material requirements have been made as flexible as possible so that they can be built from metals and plastics which are cheaply accessible in industrialized nations but also from ceramics and clays which are environmentally friendlier and more readily available in developing nations.

Thus the robotic cubes are assembled from face plates which have been manufactured and bolted to a cubic frame as illustrated in below figure.

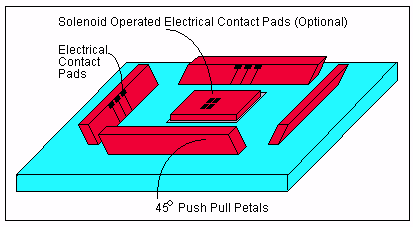

The cube therefore is empty and the plates have all the mechanisms. Each of these face plates have electrical contact pads that allow power and data signals to be routed from one robotic cube to another. The plates also have 45 degree petals that push out of the surface to connect the neighboring face that allows one robotic cube to lock to its neighbour. However, the contact pads could be on the plates themselves or be mounted separately on a purpose built solenoid operated pad as shown below.

The contact pads are arranged symmetrically around four edges help to allow for rotational regularity. These contacts are relayed out and only broadcast power when required to do so. If they are operating submerged, the contact pads can be forced into contact under pressure because of the petals, removing most of the fluid between the gaps before transmitting power through them.

A 3D rendered image of what the robotic cube looks like in practice is shown in below figure.

What is shown are four v shaped grooves running the length of the plate that allow the petals to operate so that the cubes can lock to each other and also each other using its internal mechanisms.

However, the cubes have inductive coupling to transmit power and data signals. This means that there are no connectors on the surface of the robotic cube. If the connectors are used, wiring problems may follow. Unlike contact pads, inductive coupling scale very well.