Induction Generator

Induction Generator is a popular type of 3-phase rotational machine that can be used as the wind turbine generator. Both the Synchronous and Induction Generators have similar stator winding arrangements which can energize by a rotating magnetic field and produces a three-phase (or single phase) voltage output. On the other hand, the rotors of these two machines are quite different, as the rotor of an induction generator typically consists of one of two types of arrangement: a “squirrel cage”, or a “wound rotor”.

The construction of an induction generator is based on a very common squirrel-cage induction motor type machine as it is cheap, consistent, and easily available in a wide range of electrical sizes from partial horsepower machines to multi-megawatt capacities making them ideal for use in both commercial and domestic renewable energy wind power applications.

Unlike the synchronous generator; which needs to be “synchronized” with the electrical grid before it generates the power, whereas the induction generator can be connected directly to the utility grid and driven straight by the turbines rotor blades at changeable wind speeds. In order to reduce the cost and reliability many wind power turbines use induction motors as induction, generators are driven through a mechanical gearbox to boost their speed of revolving, performance, and effectiveness.

The induction machine is also identified as “Asynchronous Machines”, that is they rotate below synchronous speed when used as a motor, and above synchronous speed when used as a generator. Thus, when rotated faster than their normal operating or no-load speed, an induction generator produces AC electricity. Because an induction generator synchronizes directly with the main utility grid – it produces electricity at the same frequency and voltage – no rectifiers or inverters are needed.

The IG provides the necessary power directly to the main utility grid, but there is a need to reactive the power supply which is provided by the utility grid. Stand alone or off-grid operation of an induction generator is also possible but the main disadvantage here is that the generator requires further capacitors connected to its windings for the self-excitation.

However, the three-phase induction machines are very well suitable for wind power and even for hydroelectric generation. These induction machines when functioning as generators have a fixed stator and a rotational rotor as same as the synchronous generators. But, the making of a magnetic field of the rotor is performed in a different way and a typical design of the rotor is the squirrel-cage structure, where conducting bars are fixed within the rotors body and then they are connected together at their ends by shorting rings as shown.

The construction of the Induction Generator

As mentioned above one of the major advantages of the Asynchronous machine is that it can be used as a generator without any additional circuitry, and it is the best voltage controller when it is connected to a three-phase mains supply. But, when an idle asynchronous generator is connected to an alternating current grid, the voltage will be inducted into the rotor winding as to as transformer with the frequency of this induced voltage being equal to the frequency of the applied voltage. However, as the squirrel cage rotors conducting bars are short-circuited together, and a magnetic field will be created inside the rotor causing the machine to rotate.

While the rotor cage magnetic field follows the stators magnetic field and accelerates up to the synchronous speed set by the frequency of the grid supply. The faster the rotor rotates; the resulting relative speed difference between the rotor cage and the rotating stator field will be lower and thus the voltage will be induced in its winding.

Even there is a possibility that the rotor rotates much slower than the mentioned synchronous speed, this will happen when the rotor reaches the synchronous speed it will get sluggish, the weakened magnetic field around the rotor is inadequate which results in the loss of friction of the rotor in idle mode. Here it is clear that an induction machine will never get to the range of its synchronous speed, if it gets to the range of the synchronous speed then there would be no current to bring into the rotors squirrel cage, there would also be the loss of magnetic field which results from no torque.

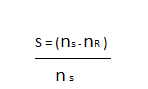

There is a difference in rational speeds, which is between the rotor and stators rotating magnetic field. This is often discussed in the induction machines as “slip”. Slip plays a key role for the torque to occur at the rotor shaft.

ns = f/p (difference in speed between stators synchronous speed) nR = (rotors actual speed in rpm) S = fractional slips of an induction machine.

Then the fractional slip s, of an induction machine is given as: S =

According to the above slip, the induction generators function is not synchronous it is referred as asynchronous. It is also referred as the slip is considerably higher when the load attached to the asynchronous generator is heavier; this is because the much heavier loads need much stronger magnetic fields.

Hence, it is concluded that the induction motors operating speeds must always not obliged to synchronous speed. While the induction generators speeds should always higher than asynchronous speed.