Intelligent Management of Electric System in Industries - II

Previously we have discussed about the Industrial plants, advanced automation, electricity distribution networks, applications that support the public distribution network management, ADA, and more. Today we will see more on the Application Functions of Data Management Systems.

Load Modeling

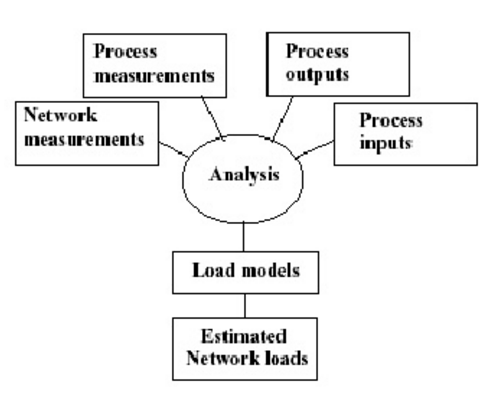

The essential basis for advanced application function is the modeling of loads connected to the networks. Usually there are only few measurement points in the network, however, loading of every load node of the network must be known in the network calculations. For that purpose the loads are estimated by load models.

The essential need for the load models is that they form a basis for the load-fow calculations. While the results for these load-flow calculations are utilized different kind of tasks as real-time network monitoring and optimization, and switching planning. Information on loads can also be utilized in preventive condition monitoring and reliability analyses.

In the domain of public electricity distribution hourly load curves have been determined for each customer group to be used in load-flow calculation and load forecasting. However; the industrial plants load modeling should be mainly based on the process itself and its behavior.

Load models can be determined by making enough measurements in different known process conditions. However, the industrial plants vary from each other, which means that load models determined in one plant may not be able to used as such in other one. One aim of the research work is to develop tools and methods by which the determination of the plant specific load models can be achieved during the installation of the automation system when enough measurements have been done and this help to know the certain process specific parameters on time. Neural networks can be used to learn the correlations between the measurements and the process in order to produce the load model. Major features of the load models are swiftness, simplicity, a capability to utilize measured information, whereas the ability to utilize inaccurate information and a capability to adapt alternating and different conditions. The state monitoring of the DMS acts in real times which appoint demands to the swiftness of the load models. Further the industrial processes will be developed and so the load models must be able to adapt in varied situations also.

Demands, mentioned above, could be achieved using advanced methods and technologies; which means using neural networks technology, fuzzy logic and self-adaptively technologies in further development of load models of the industrial distribution networks.

Load forecasting in the industrial environment cannot be based on any regularity of behavior. Reliable forecasting assumes use of methods which can utilize production plans in some time distance which also can have a large difference with each other and include inaccurate information. The load forecasting of the network feeding some process bases on the known behavior of the process4 earlier measured values and the planned production.

Calculation methods for meshed networks

The DMS for public distribution management included load flow and fault current calculation procedures4 which worked only in radial networks. The need for calculating meshed networks in industrial distribution networks is anyway obvious; (e.g. there are several fault current sources).

Load flow calculation for meshed network leads to a group of non-linear equations. Classic Newton- Raphson iteration is considered be the most competent method for solving load flow equations, and was selected as the solver. Fault current calculation is performed only in the symmetrical three-phase case. In fact, these calculations can be done simply by inverting a matrix. To calculate inverse of matrix with conventional methods is now too laborious and therefore discarded. instead an algorithm called Z-bus algorithm is used for calculating inverse effectively.

While the load-flow and fault current algorithms are implemented as a part of the DMS so that they can utilize the common network model and topology analysis. However, the primary information for the load-flow calculation is the loads of the secondary substations and motors connected to the medium voltage network. The loading information is read from the Access-database including the load models for different situations. The results of load flow and fault current calculations can be studied through the user- interface of the DMS by selecting the preferred node.

Reliability Management

The functions related to reliability have considerable economic significance in industry. While the loss of production caused by the disturbances and the inputs into the investments of the systems including maintenance and operational arrangements join here.

However the reliability can be studied with both qualitative and quantitative methods. Whereas with a qualitative analysis the possible states of the system and reasons which lead to these are determined with non-numerical methods. However, the failure modes, effects, and critically analyses are adapted generally on the qualitative methods. using failure modes, effects and critical analyses are aimed to identify those faults of the devices or of those subsystems which affect the capabilities of the system significantly. For example: availability, fault frequencies, durations of disturbances and indicators which describe the economic appreciation of interruptions can be evaluated.

However the functions supporting power distribution reliability management can be included in several different systems like; AM/FM/GIS, the Distribution Management System (DMS), SCADA system, maintenance systems, and documentation systems depending on the total concept.

The load flow calculations and short circuit calculations are the applications which have central meaning in reliability analyses. While these calculations make it possible to simulate faults, to plan relaying arrangements and network operations. Switching plans operational instructions can furthermore be stored in databases. The essential function that support reliability management and analyses the management of various instructions and documents. There are many kind of documents that can be used to support the reliability management. The graphical user-interface makes available the developing of the different sophisticated user friendly functions, for example, determination of the feeding routes of the components or loads to be examined.

The analysis of reliability technical state and capability of power distribution network is closely related to the protection co-ordination, too. Using the fault current and load-flow calculations personnel can evaluate how the distribution and the primary processes will behave in fault situations of the distribution network.

Voltage Dip Analyses

A voltage did is a sudden reduction of the supply voltage to a value between 90% and 1% of the declared voltage, followed by a voltage recovery after a short period of time. possible causes of these dips are typically faults in installations or in feeding public networks and switching of large loads example, motors. Whereas in rural areas voltage dips are generally caused by short circuit faults.

Power Quality Analyses

The term power quality - PQ is used with slightly different meanings, more to it; it can be associated with any problems in voltage, current or frequency deviations which result in failure, malfunction, combination of voltage quality and current quality, disturbances. However the voltage quality is addressed in most cases and it is concerned with many deviations of the voltage from the idea and main characteristics can also be described as with regards to the frequency, magnitude, waveform, and the symmetry of the three phase voltages and interruptions.

Condition Monitoring

There are many systems that falls under conditional monitoring in industrial processes such as rotating machines. While the online condition monitoring of components of electricity distribution network is not commonly used. However the protection relays include some functions for condition monitoring such as self diagnostics of relay and counter of operations.

Conclusion:

Requirements of intelligent software applications for supporting the operation of industrial distribution networks are dissimilar compared to the public distribution. However, the domain is more segmented and heterogeneous, and the infrastructure of automation and computer systems for electricity networks are not so sophisticated and advanced as other process automation.

If we see on the other hand the chance to apply intelligent software methods are more promising from the point of view of end8user attitudes4 because the same kind of methods have been successfully applied in process automation4 e.g. in fuzzy control and system modeling using neural networks.